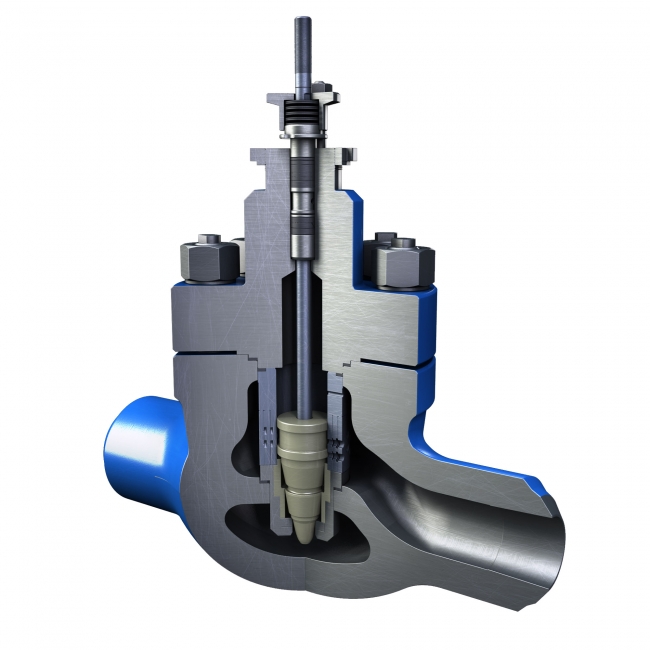

Minimum flow valve is anti-cavitation valve designed for liquid at the pressure drop up to 200 bar and flow up to 70 t/h. The valve design provides for splitting the pressure drop into six stages to subcritical pressure values causing cavitation.

We can adjust construction (design) of control valve to your individual needs. In such cases, please contact our technical support specialists.

_lxli.jpg)

Features

· Seat and a three-stage plug are made of ZrO2 ceramics, which is a material of excellent strength and chemical resistance properties.

· Valve stem is made of titanium and co-operates with sleeve packing set providing external tightness in accordance with TA Luft regulations

· possible adaptation to the construction: angle and passage

_izuh.jpg)

Construction

Minimum flow valve is anti-cavitation valve designed for liquid at the pressure drop up to 200 bar and flow up to 70 t/h.

The valve design provides for splitting the pressure drop into six stages to subcritical pressure values causing cavitation.

High quality of regulation, durability and reliability were achieved, as a result of suitable design of internal elements and material selection.

Seat and a three-stage plug are made of ZrO2 ceramics, which is a material of excellent strength and chemical resistance properties.

Further pressure drop is achieved through active throttling in three multihole hardened sleeves with radial flow.

Valve stem is made of titanium and co-operates with sleeve packing set providing external tightness in accordance with TA Luft regulations.

The valve guarantees high shut-off tightness. It is also possible to adapt this solution for other reliable applications in passage or angle designs.

We can adjust construction (design) of control valve to your individual needs. In such cases, please contact our technical support specialists

© 2016 Tair. All Rights Reserved. Tair Flow Control Co., Limited HU ICP 16035521-1 Home▏Aboutus▏Products▏Service▏Innovations▏Manufacturing▏ R& D▏Quality▏Environment▏News▏Contact